Case Study

Steam Turbine Control

Gas Turbine

Compressor & ITCC

Turbine Protection

SINOPEC Jinling Petro Unit1 is a 60MW co-generation genset, which was installed in 1990's by Shanghai Steam Turbine Works. The turbine was originally installed with hydraulic governors regulating turbine power and two extraction steam pressures. Over decades of operation, the hydraulic control system sufferred leaking, friction and deteriorated accuracy.

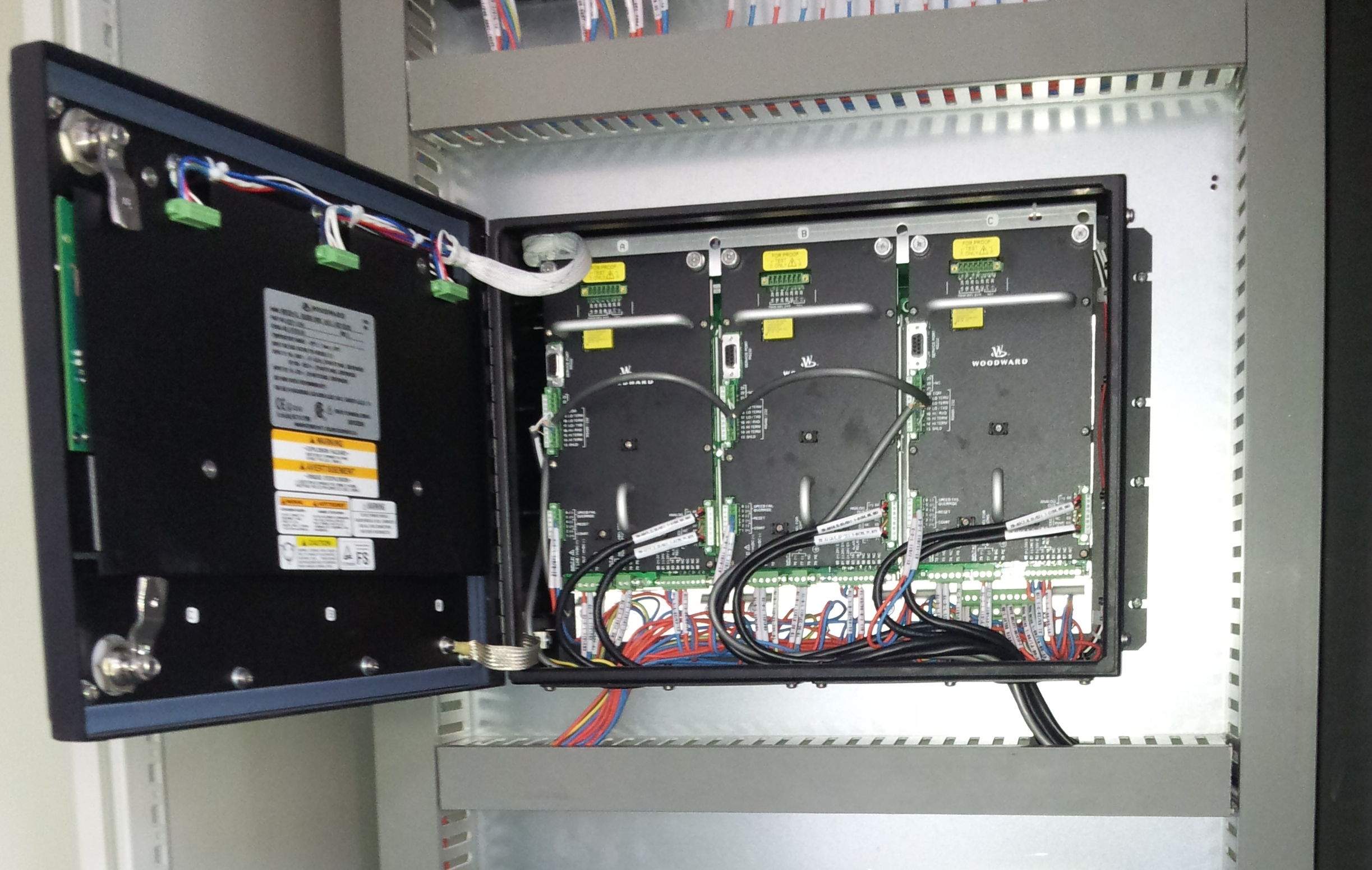

Constar upgraded the turbine hydraulic governor with Woodward Micronet TMR control system in year 2002. The upgraded DEH is TMR(Triple Module Redundancy) in hardware and powered with Ratio/Limiter algorithm. The upgraded control system not only improved reliability and accuracy, but also made operation more friendly. Since installation, the genset has been working stably and safely for almost twenty years, demonstrating the strong engineering capability of Constar.- Turbine Type: Co-Generation Genset, Double Automatic Extration Turbine

- Rated Power: 60MW

- Turbine Manufacture: Shanghai Steam Turbine Works

- Control System: Micronet TMR

- Application Type: DEH Upgrade

- Date: Year 2002

SINOPEC Jinling Petro Unit2 is a 60MW co-generation genset, which was installed in 1990's by Shanghai Steam Turbine Works. The turbine was originally installed with hydraulic governors regulating turbine power and two extraction steam pressures. Over decades of operation, the hydraulic control system sufferred leaking, friction and deteriorated accuracy.

Constar upgraded the turbine hydraulic governor with Woodward Micronet TMR control system in year 2002. The upgraded DEH is TMR(Triple Module Redundancy) in hardware and powered with Ratio/Limiter algorithm. The upgraded control system not only improved reliability and accuracy, but also made operation more friendly. Since installation, the genset has been working stably and safely for almost twenty years, demonstrating the strong engineering capability of Constar..

- Turbine Type: Co-Generation Genset, Double Automatic Extration Turbine

- Rated Power: 60MW

- Turbine Manufacture: Shanghai Steam Turbine Works

- Control System: Micronet TMR

- Application Type: DEH Upgrade

- Date: Year 2003

SINOPEC Yizheng Petro Unit3 is a 60MW co-generation genset, which was installed in 1990's by Shanghai Steam Turbine Works. The turbine was originally installed with hydraulic governors regulating turbine power and two extraction steam pressures. Over decades of operation, the hydraulic control system sufferred leaking, friction and deteriorated accuracy.

Constar upgraded the turbine hydraulic governor with Woodward Micronet TMR control system in year 2003. The upgraded DEH is TMR(Triple Module Redundancy) in hardware and powered with Ratio/Limiter algorithm. The upgraded control system not only improved reliability and accuracy, but also made operation more friendly. Since installation, the genset has been working stably and safely for almost twenty years, demonstrating the strong engineering capability of Constar.- Turbine Type: Co-Generation Genset, Double Automatic Extration Turbine

- Rated Power: 60MW

- Turbine Manufacture: Shanghai Steam Turbine Works

- Control System: Micronet TMR

- Application Type: DEH Upgrade

- Date: Year 2003

Banpu Tangshan Unit2 is a 50MW co-generation genset installed in 1990's by Harbin Steam Turbine Works. Constar supplied the turbine control system including the Woodward Micronet TMR control system with Ratio/Limiter algorithm and the TM-25 actuator that is the core of servo system. DEH system controls speed, power and two extraction pressures. The genset has been working stably and safely for almost twenty years, demonstrating the strong engineering capability of Constar.

- Turbine Type: Co-Generation Genset, Double Automatic Extration Turbine

- Rated Power: 50MW

- Turbine Manufacture: Harbin Steam Turbine Works

- Control System: Micronet TMR

- Application Type: DEH Upgrade

- Date: Year 1997

CNOOC Haihua Unit5 is a 25MW co-generation genset installed in year 2003 by Beijing Heavy Machine Works. Constar supplied the turbine control system including the Woodward Micronet TMR control system with Ratio/Limiter algorithm and the TM-25 actuator that is the core of servo system. DEH system controls speed, power and two extraction pressures. The genset has been working stably and safely for almost twenty years, demonstrating the strong engineering capability of Constar.

- Turbine Type: Co-Generation Genset, Double Automatic Extration Turbine

- Rated Power: 25MW

- Turbine Manufacture: Beijinng Heavy Machine Works

- Control System: Micronet TMR

- Application Type: DEH, New Installation

- Date: Year 2003

Meishan Steel Unit4 is a 60MW double automatic extraction co-generation genset installed in year 2004 by Shanghai Steam Turbine Works, the turbine is running with 14MPa hydraulic oil system. Constar supplied the turbine control system including the Woodward Micronet TMR control system with Ratio/Limiter algorithm. DEH system controls speed, power and two extraction pressures. The genset has been working stably and safely for almost twenty years, demonstrating the strong engineering capability of Constar.

- Turbine Type: Co-Generation Genset, Double Automatic Extration Turbine

- Rated Power: 60MW

- Turbine Manufacture: Shanghai Steam Turbine Works

- Governor Oil: 14MPa, High Pressure

- Control System: Micronet TMR

- Application Type: DEH, New Installation

- Date: Year 2004

Meishan Steel Unit6 is a 60MW double automatic extraction co-generation genset installed in year 2006 by Shanghai Steam Turbine Works, the turbine is running with 14MPa hydraulic oil system. Constar supplied the turbine control system including the Woodward Micronet TMR control system with Ratio/Limiter algorithm. DEH system controls speed, power and two extraction pressures. The genset has been working stably and safely for almost twenty years, demonstrating the strong engineering capability of Constar.

- Turbine Type: Co-Generation Genset, Double Automatic Extration Turbine

- Rated Power: 60MW

- Turbine Manufacture: Shanghai Steam Turbine Works

- Governor Oil: 14MPa, High Pressure

- Control System: Micronet TMR

- Application Type: DEH, New Installation

- Date: Year 2006

Sinpu Chemical Unit1 is a 60MW double automatic extraction co-generation genset installed in year 2005 by Shanghai Steam Turbine Works, the turbine is running with 14MPa hydraulic oil system. Constar supplied the turbine control system including the Woodward Micronet TMR control system with Ratio/Limiter algorithm. DEH system controls speed, power and two extraction pressures. The genset has been working stably and safely for almost twenty years, demonstrating the strong engineering capability of Constar.

- Turbine Type: Co-Generation Genset, Double Automatic Extration Turbine

- Rated Power: 60MW

- Turbine Manufacture: Shanghai Steam Turbine Works

- Governor Oil: 14MPa, High Pressure

- Control System: Micronet TMR

- Application Type: DEH, New Installation

- Date: Year 2005

Sinpu Chemical Unit2 is a 60MW double automatic extraction co-generation genset installed in year 2006 by Shanghai Steam Turbine Works, the turbine is running with 14MPa hydraulic oil system. Constar supplied the turbine control system including the Woodward Micronet TMR control system with Ratio/Limiter algorithm. DEH system controls speed, power and two extraction pressures. The genset has been working stably and safely for almost twenty years, demonstrating the strong engineering capability of Constar.

- Turbine Type: Co-Generation Genset, Double Automatic Extration Turbine

- Rated Power: 60MW

- Turbine Manufacture: Shanghai Steam Turbine Works

- Governor Oil: 14MPa, High Pressure

- Control System: Micronet TMR

- Application Type: DEH, New Installation

- Date: Year 2006

Sinpu Chemical Unit3 is a 50MW back pressure & extraction co-generation genset installed in year 2015 by Nanjing Steam Turbine Works, the turbine is running with 14MPa hydraulic oil system. Constar supplied the turbine control system including the Woodward Micronet TMR control system with Ratio/Limiter algorithm. DEH system controls speed, power, extraction pressure, and exhaust pressure. The genset has been working stably and safely since installation, demonstrating the strong engineering capability of Constar.

- Turbine Type: Co-Generation Genset, Extration & Exhause Pressure Turbine

- Rated Power: 50MW

- Turbine Manufacture: Nanjing Steam Turbine Works

- Governor Oil: 14MPa, High Pressure

- Control System: Micronet TMR

- Application Type: DEH, New Installation

- Date: Year 2015

Sinpu Chemical Unit4 is a 50MW back pressure & extraction co-generation genset installed in year 2016 by Nanjing Steam Turbine Works, the turbine is running with 14MPa hydraulic oil system. Constar supplied the turbine control system including the Woodward Micronet TMR control system with Ratio/Limiter algorithm. DEH system controls speed, power, extraction pressure, and exhaust pressure. The genset has been working stably and safely since installation, demonstrating the strong engineering capability of Constar.

- Turbine Type: Co-Generation Genset, Extration & Exhause Pressure Turbine

- Rated Power: 50MW

- Turbine Manufacture: Nanjing Steam Turbine Works

- Governor Oil: 14MPa, High Pressure

- Control System: Micronet TMR

- Application Type: DEH, New Installation

- Date: Year 2016

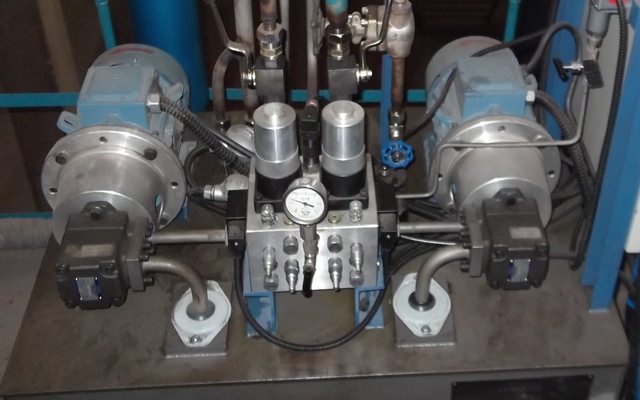

SINOPEC Shijiazhuang Unit2 is a single extraction steam turbine manufactured by Nanjing Steam Turbine Works. The turbine was installed originally with hydraulic governor, and it was experienced an unsuccessfully upgrade to digital control by other company in 2000. In 2015, Constar successfully retrofit control system with 505E controller and specially designed hydraulic system. The control performance was very satisfied and the turbine has been running stably and safely since then.

- Turbine Type:Single Extraction Steam Turbine

- Rated Power:25MW

- Turbine Manufacture:Nanjing Steam Turbine Works

- Control System:505E

- Project Type:DEH System

- Project Date:Year 2015

There are two LM2500+ gas turbines in Liyuan power plant. The turbines are controlled by Woodward Micronet Plus system with GS16 gas metering valves. Constar has been supporting the customer in both technical consulting and retrofit activities for many years.

- Turbine: LM2500+

- Power: 25MW

- Turbine Manufacture: GE

- Control System: Micronet Plus

- Application Type: Gas Turbine Control

- Date: Year 2012

The gas turbine in Huadian Xinjiang is controlled by Woodward Netcon Controller which is an obsolete prodcut, and Constar offered site service on trouble shooting.

- Turbine Type: Gas Turbine

- Turbine Manufacture: Pratt & Whitney

- Control System: NetCon

- Application Type: Gas Turbine Control System

- Date: Year 2010

Constar solved the HMI communication problem, improved the HMI function and developed software to backup and transfer the log data automatically.

- Turbine Type: Gas Turbine

- Turbine Manufacture: GE

- Product: Micronet

- Application Type: Gas Turbine Control System

- Date: Year 2017

A Chinese local gas turbine manufacture developed a dual fuel gas turbine and Constar supplied the liquid fuel metering valve with turbine testing assistance.

- Turbine Type: Local Gas Turbine

- Turbine Manufacture: A Local Gas Turbine Manufacture

- Product: Liquid Fuel Metering Valve

- Application Type: Liquid Fuel Metering Valve for Gas Turbine

- Date: Year 2017

鞍山钢铁十三号机组是二十世纪引全套进口汽轮鼓风机组,汽轮机是Sulzer机组,风机是Brown Boveri鼓风机。机组最初的控制系统是机械液压调节方式, 控制精度不好、操作复杂、维护不方便。随着投运时间的增加,机械磨损和控制精度差等问题增多。

控之星自动化采用Woodward公司优秀的505数字控制器和西门子PLC系统,并采用优秀的汽轮机和压缩机防喘算法成功地实施了汽轮机和压缩机综合控制系统改造,不仅使古老的机组能够继续为鞍钢的生产贡献力量,而且提高了机组效率和操作自动化水平。

- 机组类型:汽轮鼓风机组

- 机组功率:22.8MW

- 机组制造商:Sulzer

- 控制器:505/PLC

- 项目类型:ITCC

- 项目日期:2015年

鞍山钢铁十五号机组是二十世纪引全套进口汽轮鼓风机组,汽轮机是Sulzer机组,风机是Brown Boveri鼓风机。机组最初的控制系统是机械液压调节方式, 控制精度不好、操作复杂、维护不方便。随着投运时间的增加,机械磨损和控制精度差等问题增多。

控之星自动化采用Woodward公司优秀的505数字控制器和西门子PLC系统,并采用优秀的汽轮机和压缩机防喘算法成功地实施了汽轮机和压缩机综合控制系统改造,不仅使古老的机组能够继续为鞍钢的生产贡献力量,而且提高了机组效率和操作自动化水平。

- 机组类型:汽轮鼓风机组

- 机组功率:22.8MW

- 机组制造商:Sulzer

- 控制器:505/PLC

- 项目类型:ITCC

- 项目日期:2016年

丽东化工103机组是Ebara-Elliott汽轮压缩机组,控之星自动化采用Woodward公司优秀的5009 TMR三冗余控制系统、TM-25执行机构和优秀的汽轮控制算法成功地实施了汽轮机控制系统改造,不仅使古老的机组能够继续为青岛丽东的生产贡献力量,而且提高了机组效率和操作自动化水平。

- 机组类型:汽轮压缩机组

- 机组制造商:Ebara-Elliott

- 控制器:5009 TMR

- 项目类型:DEH

- 项目日期:2017年

丽东化工107机组是Ebara-Elliott汽轮压缩机组,控之星自动化采用Woodward公司优秀的5009 TMR三冗余控制系统、TM-25执行机构和优秀的汽轮控制算法成功地实施了汽轮机控制系统改造,不仅使古老的机组能够继续为青岛丽东的生产贡献力量,而且提高了机组效率和操作自动化水平。

- 机组类型:汽轮压缩机组

- 机组制造商:Ebara-Elliott

- 控制器:5009 TMR

- 项目类型:DEH

- 项目日期:2017年

丽东化工109机组是Ebara-Elliott汽轮压缩机组,控之星自动化采用Woodward公司优秀的5009 TMR三冗余控制系统、TM-25执行机构和优秀的汽轮控制算法成功地实施了汽轮机控制系统改造,不仅使古老的机组能够继续为青岛丽东的生产贡献力量,而且提高了机组效率和操作自动化水平。

- 机组类型:汽轮压缩机组

- 机组制造商:Ebara-Elliott

- 控制器:5009 TMR

- 项目类型:DEH

- 项目日期:2017年

三友化工一号机组是辽宁汽轮动力汽轮压缩机组,控之星自动化采用Woodward公司优秀的Micronet Plus控制系统和优秀的汽轮控制算法成功地实施了汽轮机控制系统改造,具有系统可靠、控制精度高、算法先进的特点。

- 机组类型:汽轮压缩机组

- 机组制造商:辽宁汽轮动力

- 控制器:Micronet

- 项目类型:汽轮机控制系统

- 项目日期:2015年

三友化工二号机组是辽宁汽轮动力汽轮压缩机组,控之星自动化采用Woodward公司优秀的Micronet Plus控制系统和优秀的汽轮控制算法成功地实施了汽轮机控制系统改造,具有系统可靠、控制精度高、算法先进的特点。

- 机组类型:汽轮压缩机组

- 机组制造商:辽宁汽轮动力

- 控制器:Micronet

- 项目类型:汽轮机控制系统

- 项目日期:2016年

DUNAN Group Unit1 steam turbine was manufactured by Harbin GHPOWER and Constar designed and installed control and protection system on the rest of 505 and Protech GII. The turbine & compressor set was put into operation in 2015 with a satisfied performance.

- Turbine Type:Compressor Driving Turbine

- Rated Power:25MW

- Turbine Manufacture:Harbin GHPOWER

- Control System:505 & Protech GII

- Project Type:Turbine Control & Protection System

- Project Date:Year 2015

田湾核电三号机组是哈尔滨汽轮机厂生产的百万核电机组,控之星自动化采用Woodward公司优秀的Micronet TMR三冗余控制系统和优秀的汽轮保护算法成功地实施了汽轮机ETS保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:核电汽轮机组

- 机组制造商:哈尔滨汽轮机厂

- 控制器:Micronet

- 项目类型:汽轮机保护系统

- 项目日期:2017年

田湾核电四号机组是哈尔滨汽轮机厂生产的百万核电机组,控之星自动化采用Woodward公司优秀的Micronet TMR三冗余控制系统和优秀的汽轮保护算法成功地实施了汽轮机ETS保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:核电汽轮机组

- 机组制造商:哈尔滨汽轮机厂

- 控制器:Micronet

- 项目类型:汽轮机保护系统

- 项目日期:2017年

大唐高井一号机组是哈尔滨汽轮机厂生产的联合循环汽轮机组,控之星自动化采用Woodward公司优秀的Protech GII三冗余保护系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:联合循环汽轮机组

- 机组制造商:哈尔滨汽轮机厂

- 控制器:Protech GII

- 项目类型:汽轮机三冗余超速保护系统

- 项目日期:2012年

大唐高井二号机组是哈尔滨汽轮机厂生产的联合循环汽轮机组,控之星自动化采用Woodward公司优秀的Protech GII三冗余保护系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:联合循环汽轮机组

- 机组制造商:哈尔滨汽轮机厂

- 控制器:Protech GII

- 项目类型:汽轮机三冗余超速保护系统

- 项目日期:2012年

宁波动力一号机组是哈尔滨汽轮机厂生产的联合循环汽轮机组,控之星自动化采用Woodward公司优秀的Protech GII三冗余保护系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:联合循环汽轮机组

- 机组制造商:哈尔滨汽轮机厂

- 控制器:Protech GII

- 项目类型:汽轮机三冗余超速保护系统

- 项目日期:2014年

宁波动力二号机组是哈尔滨汽轮机厂生产的联合循环汽轮机组,控之星自动化采用Woodward公司优秀的Protech GII三冗余保护系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:联合循环汽轮机组

- 机组制造商:哈尔滨汽轮机厂

- 控制器:Protech GII

- 项目类型:汽轮机三冗余超速保护系统

- 项目日期:2014年

中海油海化六号机组是北重生产的热电联产抽凝式汽轮机组, 控之星自动化采用双冗余PLC系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:单抽汽轮机组

- 机组制造商:北重

- 控制器:PLC

- 项目类型:汽轮机ETS系统

- 项目日期:2012年

中海油海化七号机组是青岛捷能汽轮机厂生产的热电联产抽凝式汽轮机组, 控之星自动化采用双冗余PLC系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:单抽汽轮机组

- 机组制造商:青岛捷能汽轮机厂

- 控制器:PLC

- 项目类型:汽轮机ETS系统

- 项目日期:2012年

中海油海化八号机组是青岛捷能汽轮机厂生产的热电联产抽凝式汽轮机组, 控之星自动化采用双冗余PLC系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:单抽汽轮机组

- 机组制造商:青岛捷能汽轮机厂

- 控制器:PLC

- 项目类型:汽轮机ETS系统

- 项目日期:2012年

华能临港机组是哈尔滨汽轮机厂生产的联合循环汽轮机组,控之星自动化采用Woodward公司优秀的Protech GII三冗余保护系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:联合循环汽轮机组

- 机组制造商:哈尔滨汽轮机厂

- 控制器:Protech GII

- 项目类型:汽轮机三冗余超速保护系统

- 项目日期:2014年

Zouping Power Unit1是哈尔滨汽轮机厂生产的联合循环汽轮机组,控之星自动化采用Woodward公司优秀的Protech GII三冗余保护系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:联合循环汽轮机组

- 机组制造商:哈尔滨汽轮机厂

- 控制器:Protech GII

- 项目类型:汽轮机三冗余超速保护系统

- 项目日期:2016年

Zouping Power Unit2 是哈尔滨汽轮机厂生产的联合循环汽轮机组,控之星自动化采用Woodward公司优秀的Protech GII三冗余保护系统成功地实施了汽轮机独立电超速保护系统, 具有系统可靠、响应速度快、控制精度高、算法先进的特点。

- 机组类型:联合循环汽轮机组

- 机组制造商:哈尔滨汽轮机厂

- 控制器:Protech GII

- 项目类型:汽轮机三冗余超速保护系统

- 项目日期:2016年